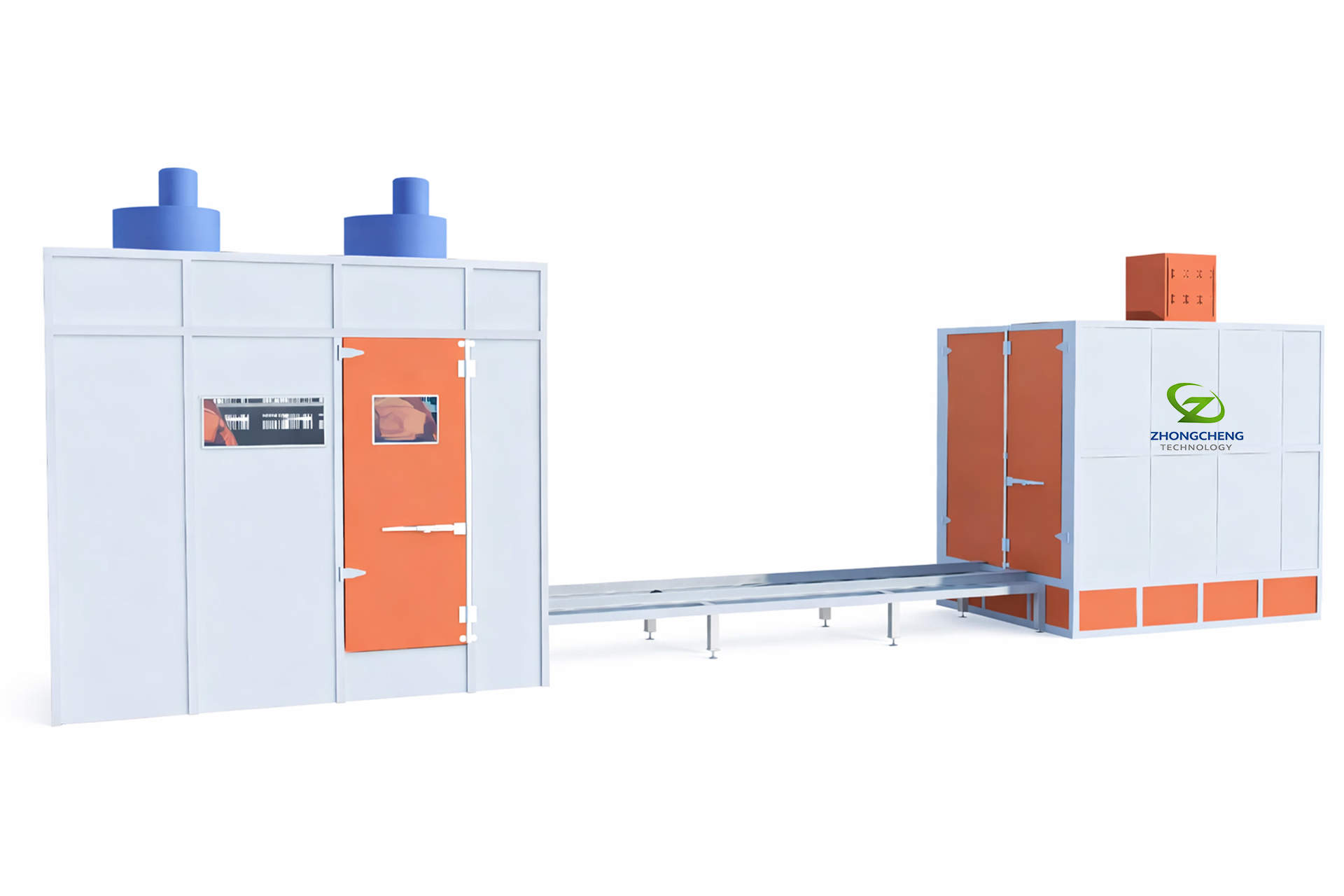

Manual Painting Production Line

The manual coating line ensures that each workpiece is coated with high quality through manual operation and precise control. Here are the main production processes of a manual painting line:

1. Pre-treatment stage

Pre-treatment is the first step in a manual painting line to ensure a clean, flat surface of the workpiece and provide good adhesion to the coating. The pre-treatment process includes:

Cleaning and degrease: Use cleaning agents to remove oil, stains, and dust from the surface of the workpiece.

Rust removal and pickling: If there is rust on the surface of the workpiece, use pickling solution to remove rust to ensure a smooth surface and avoid insufficient coating adhesion.

Phosphating treatment: The phosphating solution treats the surface of the workpiece to form a phosphate protective film, effectively enhancing the adhesion of the coating.

Drying: Use drying equipment to completely dry the surface of the workpiece to prevent moisture from affecting the adhesion of the coating.

The pre-treatment process ensures that the painted surface is in ideal condition, providing a solid foundation for adhesion and durability in subsequent coatings.

2. Spraying stage

During the spraying stage, the spray gun is manually operated to evenly spray the paint onto the surface of the workpiece, creating the desired coating. Key technologies for the spraying process include:

Spray gun selection and adjustment: Manually adjust the spray angle, spraying amount and spraying pressure of the spray gun according to the coating type and coating requirements to ensure that the coating covers the workpiece evenly.

Manual Spraying Operation: The operator performs manual spraying according to the shape, size, and surface requirements of the workpiece. Operators often need to constantly adjust the angle and distance of the spray gun to ensure uniform coatings and no leakage or buildup.

Interlayer inspection and trimming: After each layer of coating is completed, the operator checks the spraying effect and trims the uneven areas in time to ensure the surface is smooth and defect-free.

The spraying phase relies on the skill and experience of the operator, who can flexibly adjust the spraying process according to specific needs.

3. Curing stage

The painted workpiece needs to be cured by baking to achieve the desired hardness and durability of the coating. The curing process includes:

Baking equipment: The workpiece enters the oven to cure the paint through high temperature. Temperature and time control is critical to coating quality.

Temperature control: The baking temperature typically ranges from 160°C to 200°C, depending on the type of coating and the workpiece requirements. Temperatures that are too high or too low can affect the quality of the coating.

Curing Time: Set the appropriate baking time based on the coating thickness and coating characteristics to ensure that the coating is fully cured and achieves optimal performance.

The cured coating is hard and durable, with scratch-resistant, corrosion-resistant, and antioxidant properties.

4. Inspection and Touch-Up

The coated workpieces need to undergo strict quality inspection to ensure that each workpiece meets the requirements. The inspection process includes:

Visual Inspection: Check the surface of the workpieces for bubbles, sagging, brush marks, and other defects to ensure the coating is even and flawless.

Coating Thickness Measurement: Use a coating thickness gauge to measure the coating thickness and ensure it meets the specified standards.

Adhesion Test: Conduct tests such as pull-off tests and scratch tests to ensure good adhesion between the coating and the substrate, preventing easy peeling.

If any issues are found, operators will perform touch-ups and re-coating to ensure each workpiece meets the customer’s quality requirements.

5. Packaging and Shipping

Workpieces that pass inspection will proceed to the packaging stage. At this point, the workpieces have excellent appearance and performance, and are ready to be shipped to customers. The packaging process includes:

Selection of Packaging Materials: Choose appropriate packaging materials (such as foam, cartons, wooden boxes, etc.) based on the type of workpiece and transportation requirements.

Labeling and Documentation: Mark each workpiece with the production date, coating type, and other relevant information to ensure product traceability for the customer.

After packaging, the workpieces will be shipped according to the order schedule, ensuring on-time delivery to the customer.

The manual coating production line, through a series of stages including pretreatment, spraying, curing, inspection, and packaging, ensures that each product achieves a high-standard coating finish. Although manual operations rely on workers’ skills, they can provide highly customized services to accommodate different workpieces and small-batch production needs.

Through meticulous processes and strict quality control, the manual coating production line can still provide customers with high-quality coating results, meeting the coating requirements of various industries.