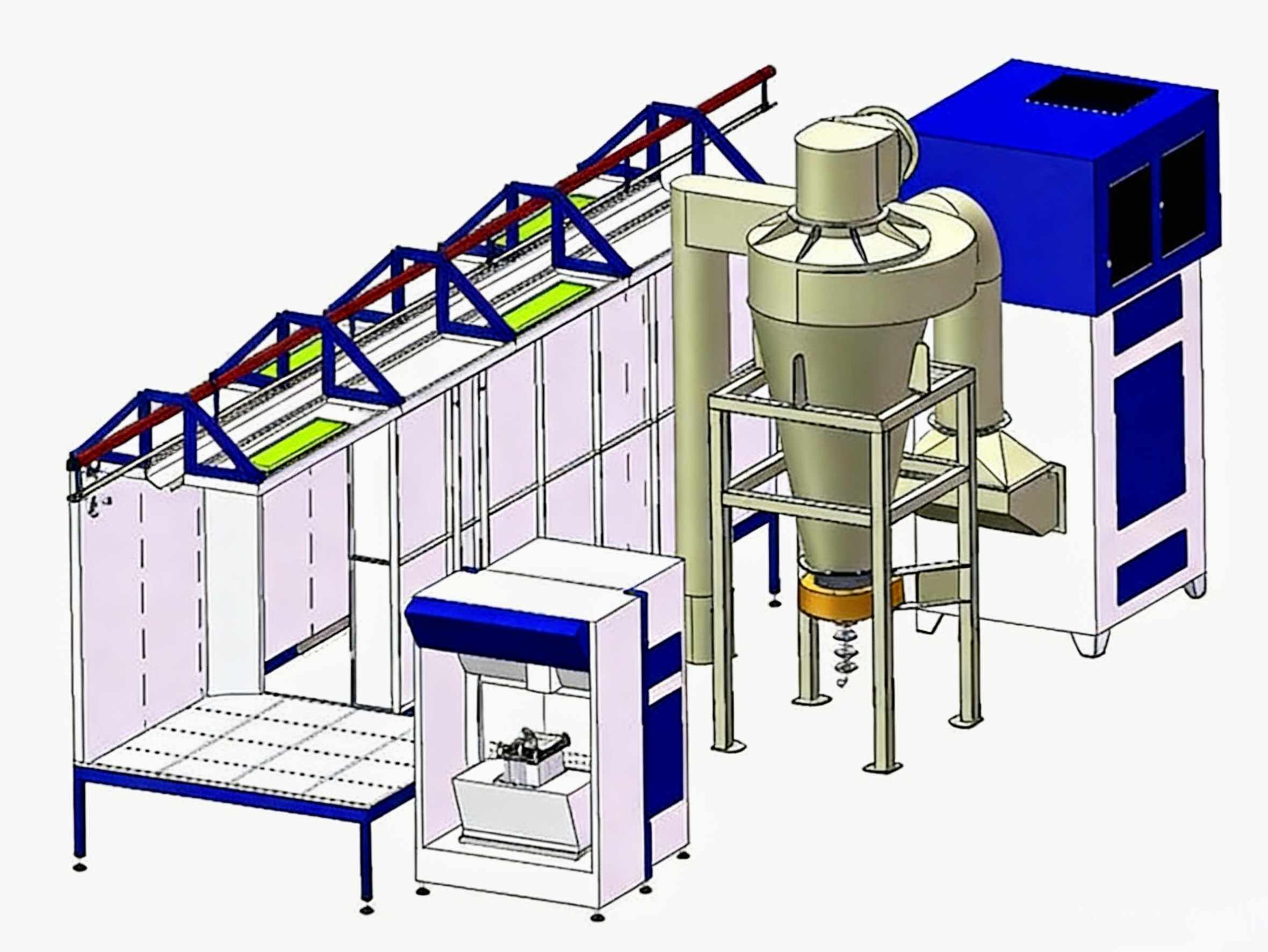

Cyclone Powder Recovery System

The cyclone powder recovery system is a common and efficient powder recovery device, mainly used to recover powder coatings that do not adhere to the workpiece during the powder coating process. It uses the principle of cyclone separation, using airflow to separate powder from air, thus achieving efficient powder recovery.

1. Suction Airflow

During the powder coating process, the powder coating sprayed from the spray gun mixes with air and is sprayed onto the surface of the workpiece. When the powder coating fails to adhere to the workpiece, this powder is carried away by the air and enters the recovery system.

Airborne Powder: The air carries the powder coating that did not adhere along the pipeline into the cyclone recovery system.

Airflow Control: The system controls the airflow speed through a fan to ensure efficient separation of powder and air.

2. Cyclone Separation Principle

The core principle of the cyclone powder recovery system is the use of cyclone separation technology. The cyclone separator in the system uses high-speed rotating airflow to separate gas from powder.

Rotating Airflow: The airflow entering the cyclone separator is forced to rotate inside the separator, producing centrifugal force.

Centrifugal Force Action: Due to the centrifugal force, heavier powder coatings are thrown toward the outer wall of the separator, while lighter air is discharged through the central pipe.

3. Powder Collection

After cyclone separation, the powder coating is separated and settled into the powder hopper or dust collection device at the bottom of the separator. The key in this process is ensuring efficient powder collection and subsequent reuse.

Powder Settling: The bottom of the cyclone separator has a powder collection hopper, where centrifugal force concentrates the powder toward the outer wall and it eventually falls into the collection hopper.

Powder Recovery: The settled powder is collected through pipes or automated devices and sent to a powder storage unit for reuse.

4. Exhaust and Airflow Circulation

The separated air is discharged through the top exhaust outlet of the cyclone separator, usually passing through a filter to remove remaining powder particles, ensuring that the emitted air meets environmental standards.

Air Filtration: During exhaust, air passes through a filter to remove fine powder particles, ensuring clean emissions.

Airflow Circulation: The discharged air can be redirected to other equipment or the environment, achieving airflow recycling.

5. Powder Reuse

The recovered powder, after cleaning and sieving, can be reused. This process includes:

Screening: The recovered powder usually needs to be screened to remove impurities and oversized particles to ensure coating quality.

Reuse: The screened powder coating is then sent back into the spraying system to continue the coating process, reducing powder waste.

The cyclone powder recovery system uses the principle of cyclone separation to separate powder coating from air through centrifugal force, achieving efficient powder recovery. The recovered powder can be reused after screening, significantly reducing powder waste, lowering production costs, and meeting environmental protection requirements. This system is widely used in powder coating production lines, enhancing the economic efficiency and environmental friendliness of the coating process.