Cumhdach gabhálais líne a tháirgeadh

A fully automatic painting production line is usually composed of multiple key components and equipment, which work together to ensure the efficiency, precision, and consistency of the entire painting process. The following are common components of a fully automatic painting production line and their functions:

1. Spraying System

Spray Gun: This is a core component of the painting process, responsible for evenly spraying paint onto the surface of the workpiece. Different types of spray guns can be selected based on the type of paint and spraying method (such as electrostatic spraying, pneumatic spraying, etc.).

Spraying Robot: Used in high-precision and large-scale production, an automatic spraying robot can accurately control the position, angle, and path of the spray gun to ensure uniform coating.

Electrostatic Spraying Equipment: Utilizes electrostatic force to attract powder coating to the surface of the workpiece, reducing waste and ensuring adhesion and uniformity of the coating.

2. Pretreatment System

Cleaning Equipment: Used to remove oil, dust, and impurities from the surface of the workpiece, typically including spray washers and ultrasonic cleaners.

Rust Removal Equipment: Used to remove oxides and rust from the surface of metal workpieces, commonly including sandblasting machines and pickling tanks.

Phosphating Equipment: Forms a phosphate film through chemical reactions to enhance coating adhesion and prevent rust.

Drying Equipment: Used to quickly evaporate moisture and solvents from the workpiece surface, usually with hot air dryers.

3. Paint Delivery System

Paint Delivery Pipeline: Used to transport paint from the paint tank to the spray gun or spraying robot via airflow, pumping, or pressure.

Paint Mixing Device: Ensures that the paint remains uniform during spraying to avoid sedimentation or uneven curing agent distribution.

4. Curing System

Curing Oven: Used to heat and cure the paint, commonly including infrared ovens, hot air circulation ovens, or high-temperature curing furnaces. The paint undergoes a chemical reaction at the curing temperature to form a hard coating.

Cooling System: After curing, the workpiece needs to be cooled through the cooling system to ensure coating stability.

5. Drying and Curing System

Drying Oven: Used to remove moisture and solvents from the workpiece surface before paint curing to ensure coating quality.

Infrared Heater: Uses efficient infrared radiation heating to quickly dry the paint surface, commonly used for rapid curing.

6. Automation Control System

PLC Controller: The automated control system for the entire production line, responsible for coordinating the operation of various devices to ensure the stability of the process flow.

Touchscreen Control Panel: Operators monitor the production line status and adjust parameters (such as spray volume, curing temperature, etc.) via the touchscreen panel.

Sensors and Monitoring Systems: Monitor key parameters during the coating process (such as coating thickness, spray volume, paint flow, etc.) to ensure coating quality.

7. Powder Recovery System

Powder Recovery Machine: Used to recover powder coating that does not adhere to the workpiece during spraying. The recovery system maximizes powder utilization through suction, filtration, and circulation technology, reducing waste.

Filtration Device: During powder recovery, the filtration device removes fine powder particles from the air to ensure a clean working environment.

8. Ventilation and Exhaust System

Exhaust System: Used to remove harmful gases, solvent vapors, and airborne dust generated during the coating process, ensuring a safe and environmentally friendly working environment.

Ventilation Equipment: Maintains air circulation in the coating area to prevent paint or harmful gases from accumulating in the air.

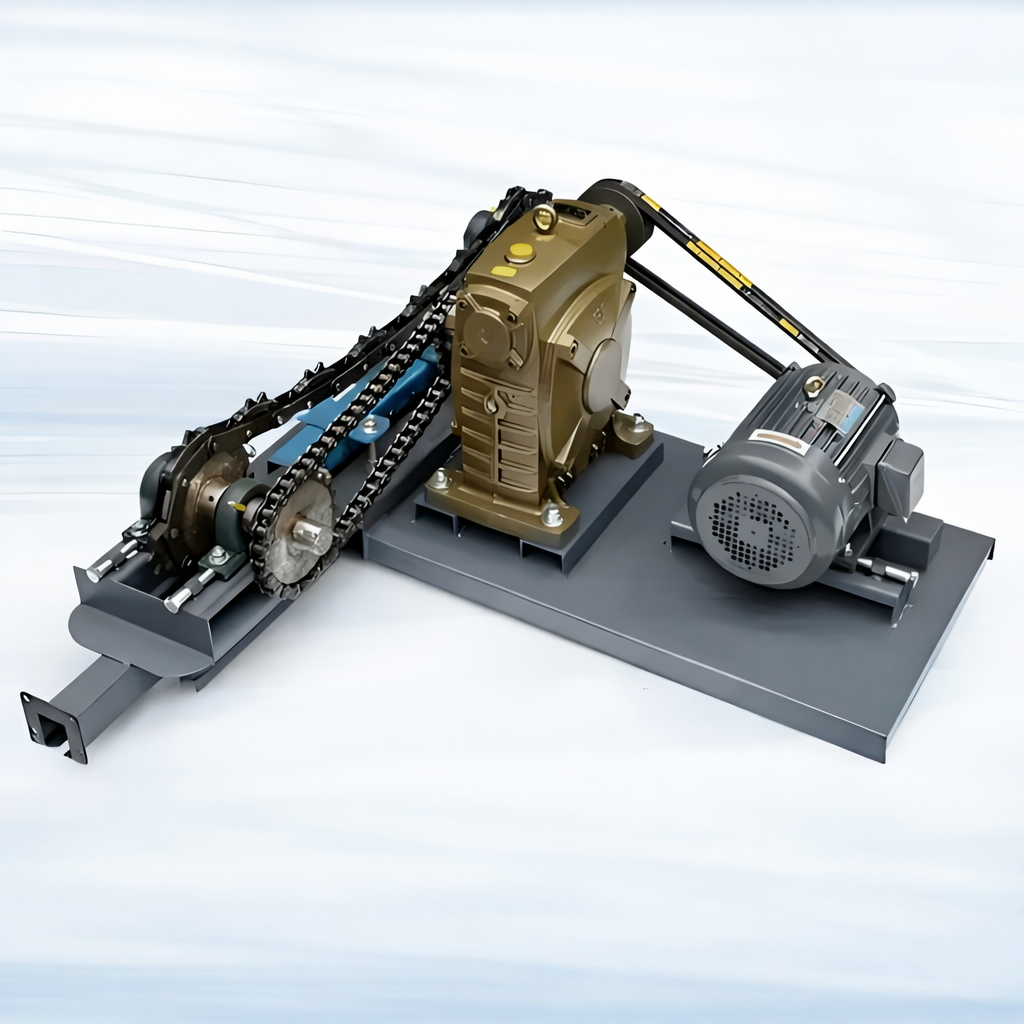

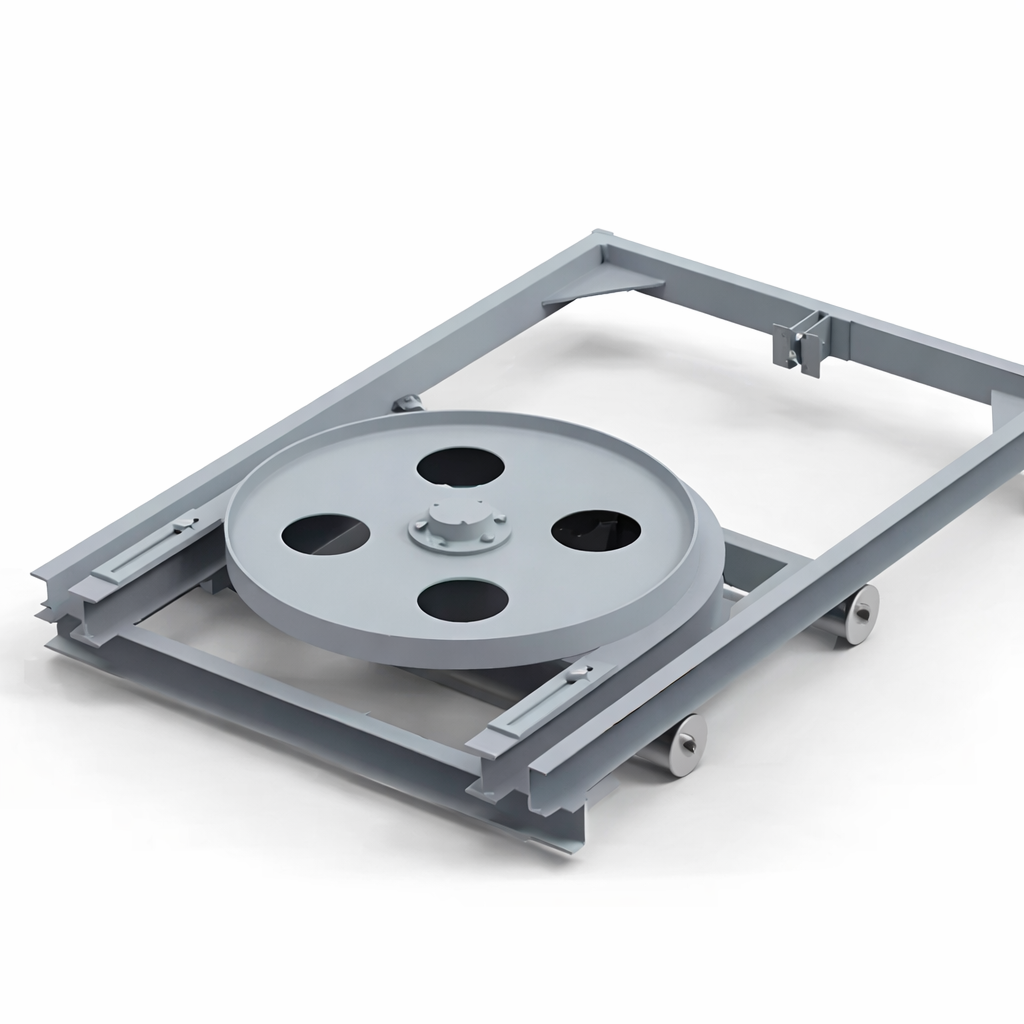

9. Conveyor System

Conveyor Line: Used to transport workpieces between different stages of the production line. Common types include chain conveyors, roller conveyors, and belt conveyors according to needs.

Lifting and Loading Machines: Used for vertical transport of workpieces when required, ensuring smooth production line operation.

10. Quality Inspection and Control Equipment

Coating Thickness Gauge: Used to detect the thickness of the coating on workpiece surfaces to ensure each workpiece meets standards.

Vision Inspection System: Uses cameras and image processing technology to monitor the quality of the surface coating in real-time, checking for defects such as bubbles, sagging, or uneven coating.

Adhesion Testing Equipment: Used to test the adhesion of the coating to ensure sufficient bonding strength between the paint and the workpiece surface, preventing coating detachment.

Accessories for a fully automatic coating production line cover all aspects from pretreatment, spraying, curing, quality inspection to environmental recovery. Through the integrated combination of these accessories and automated control, the efficiency of the coating process, stability of coating quality, and compliance with environmental requirements can be ensured. With continuous technological advancement, more efficient, energy-saving, and environmentally friendly accessories are being integrated into fully automatic coating production lines, greatly improving production efficiency and product quality.